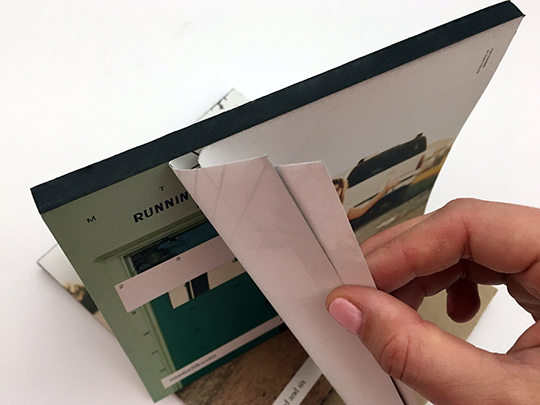

We produce pads in quantities from 1000’s to 10’s of thousands. As usual most of our pad jobs are unusual. Some we “shape” with one of our three PMC high die cutting machines. We have one of the few PMC machines that can shape cut sizes up to 9” x 11”! We also do folds and fold-out pads where each sheet in the pad might be folded with 2 or 3 or 4 panels. These pads are challenging because the open edge of the pad is much thicker than the padded edge, stacking the pads in high piles and applying glue simply does not work. We produce giant pads sure as measurements maybe 8.5” x 14” x 1” thick (padding on the short side), using hot melt glue on our “Kansas” padding machine. Using regular cold glue for a pad this big, would mean with the weight of the pad it would tear apart. We can also add special colouring to the glue and produce pads with a range of over 50 different colours. This process is very cost effective…strongly differentiating the product, and adding (at least) a perception of “value added.”