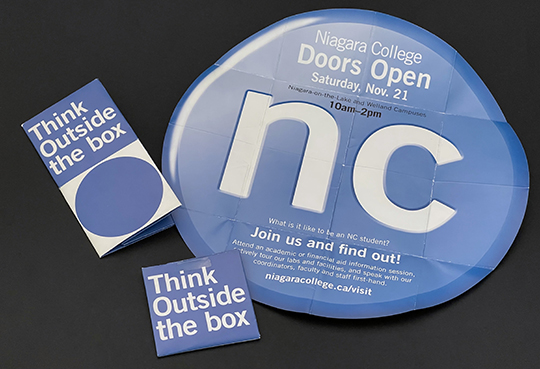

Look at how many folds this Circle has – We did all 6 folds automatically!

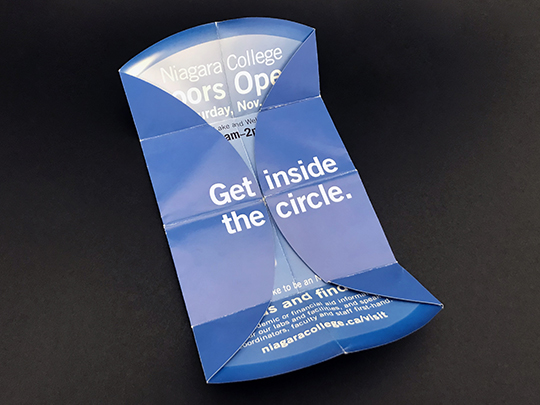

How do other binderies fold a die cut circle? Most would start with a die cut circle that has one corner that’s perforated. The sheet would be folded like any other, (but limited to one or two folds) and then the perforated section would be hand stripped to reveal the final circle. This method has 3 problems:

1) This method is time consuming and costly;

2) Most are limited to doing only two folds; and

3) The final circle has the leftover perforations marks!

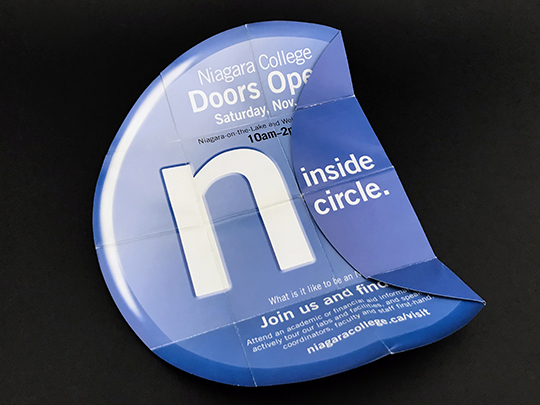

How does our bindery make a Folded Circle without any perf marks? We are always innovating, and Folding Circles is something we can do completely automatically and without any perforations.

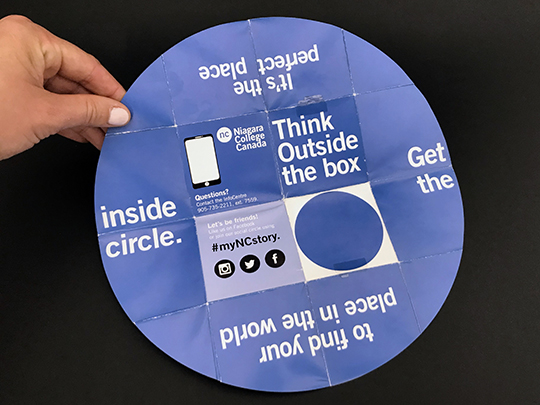

First, we cut sheets with our PMC / High Die Cutting machines to cut ultra smooth Circles. Then we fold the Circles on an extremely rare folding machine that has no register table or side guides. We simply place a 4-inch pile of PMC / High Die Cut circles into the hopper and the folding machine catches the bottom circle and brings it right onto the folding plates. From there, we do 6 folds and produce a smooth Folded Circle that has a clip seal / wafer seal.

These are the benefits of our method:

1. PMC / High Die Cutting is a much cheaper way to cut circles than die cutting

2. PMC / High Die Cutting produces smooth edged circles without perf marks

3. We can do up to 6 folds all automatically and add a clip seal / wafer seal

Notice how many folds this piece has! If you need PMC / High Die Cut Circles folded once, twice or up to six times, please make us your first call!