What I’m showing in this video and still pictures what are usually simply called a “Binder.” An older but more descriptive term is “ring binder.” An even older term is “loose-leaf ring binder.” The main purpose of a binder is to enable the user to add or remove sheets. As explained in the video, the vast majority of binders are vinyl binders followed by case-wrapped binders and then binders made out of polyethylene.

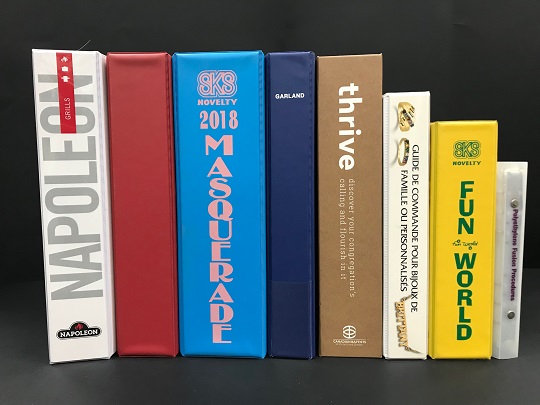

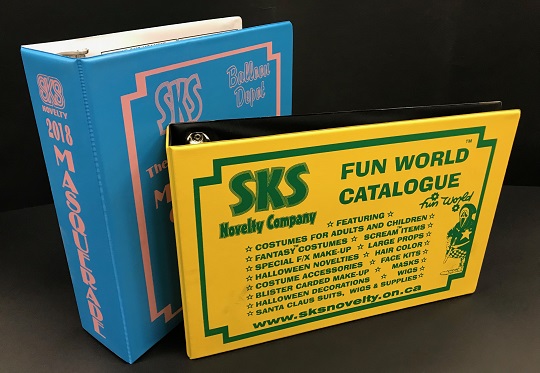

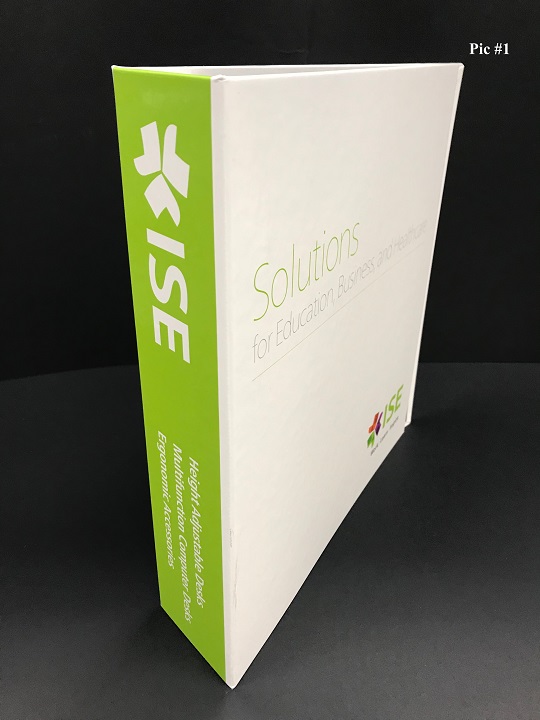

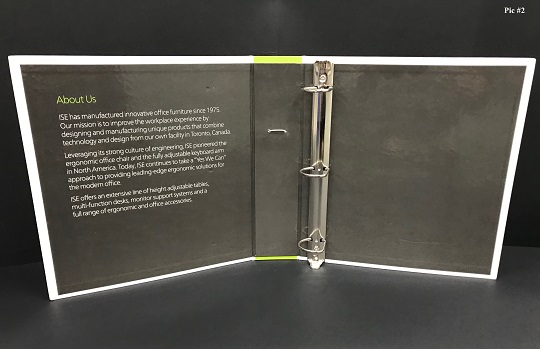

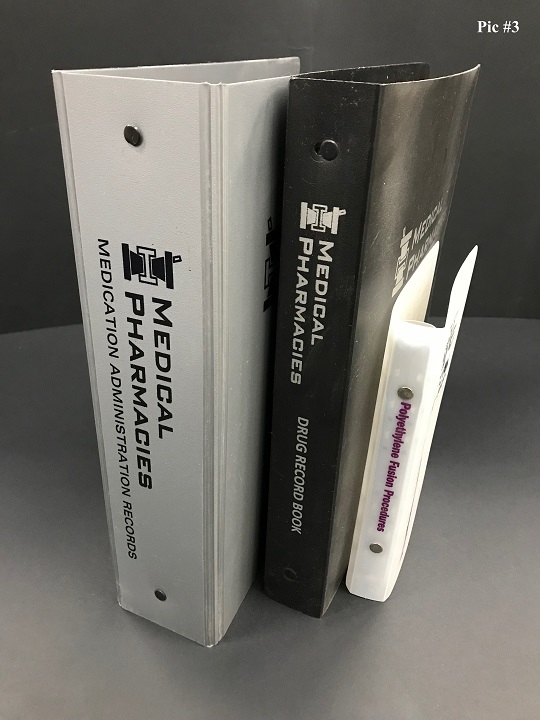

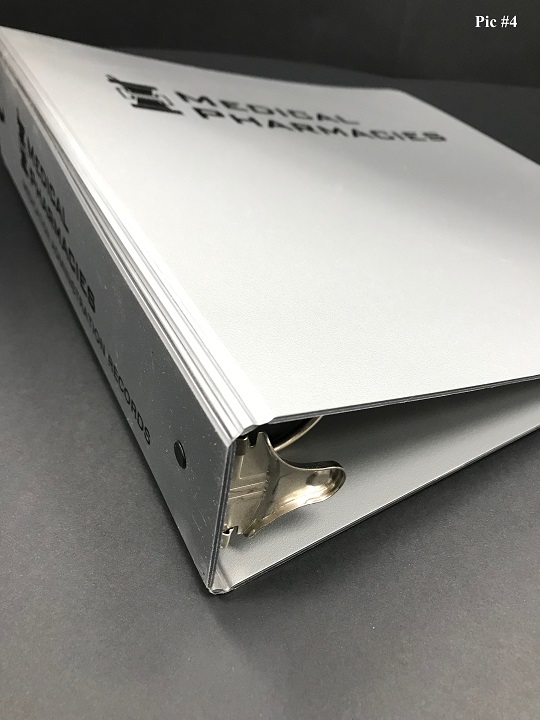

Picture #1 and #2 are case wrapped binders. Picture #3 and #4 shows polyethylene binders.

All three styles can be screen printed or foil stamped. By far the most durable would be polyethylene binders and the other two would be tied for second for durability. There are too many variables to say which of the three is the cheapest (the new term for cheap is cost-effective!). Vinyl binders allow the addition of clear pockets much more cost effectively than the other two.

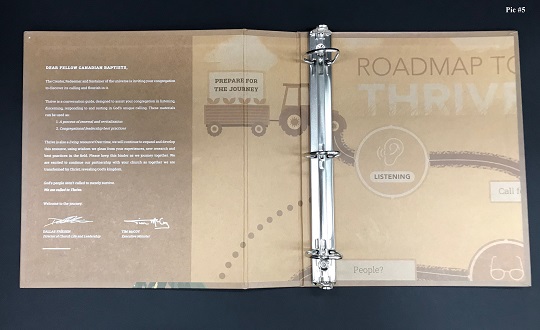

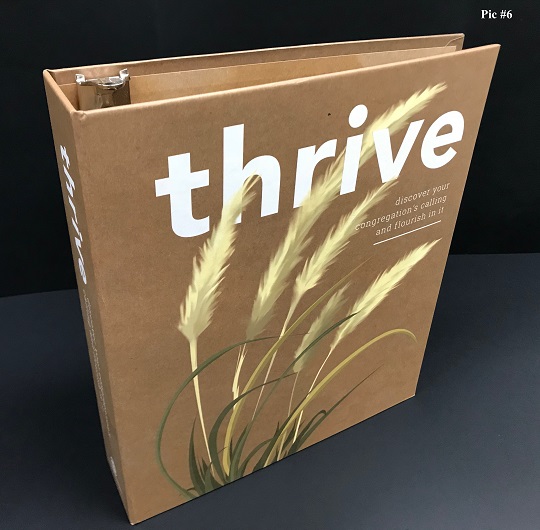

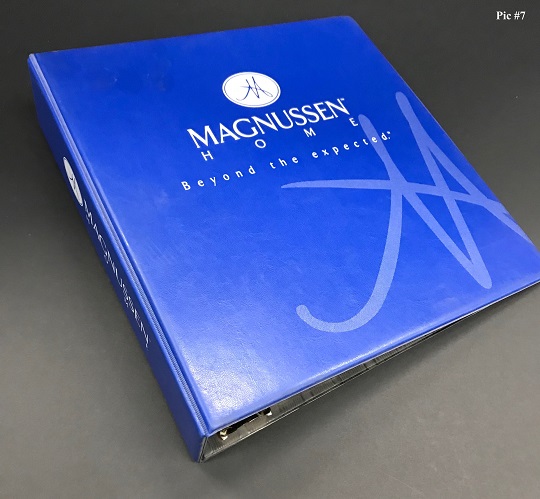

Picture #5 and #6 shows a case wrapped binder. Picture #7 is a silk screened binder.

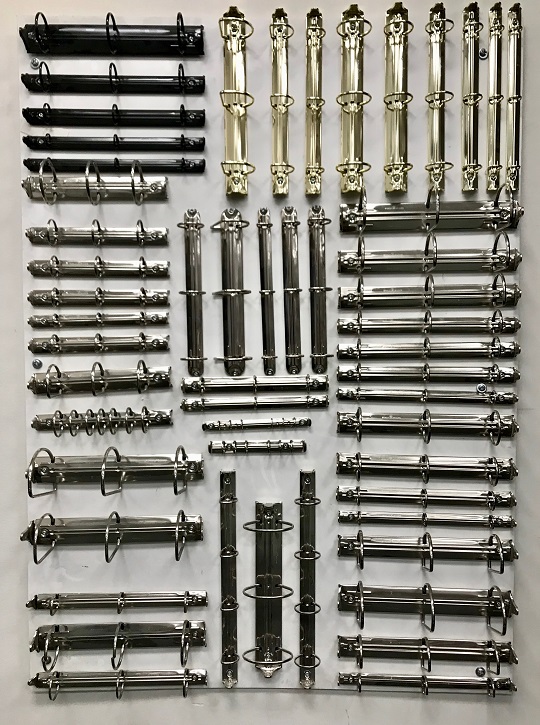

There are over 3,000 different styles, capacities, lengths, closing mechanism, colours and widths of rings metals to chose from. When writing specifications for binders, the commonest and often the most disastrous mistake is to measure the width of the spine of the binder rather than measuring the inside size of the metal ring mechanism!