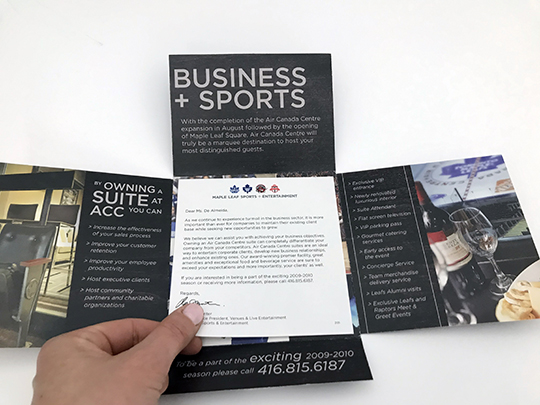

The challenge of a Cross Fold piece like this one isn’t the die cutting or folding. Gluing the inserts onto the Cross Folder is the typical way of doing this job. But, as you can see in the video and the image below, the insert on the centre panel is not attached by glue! A piece like this is produced automatically and in just one pass, which reduces spoilage and the cost of the job.

How can we produce a job like this automatically? As we frequently do, we have a trick up our sleeve! We use a tipping machine to “tip” the sheet on the centre panel with a drop of water. The drop of water temporarily holds the insert in place as the carrier travels through the machine. This piece has one wafer/clip seal, but we can apply 1, 2 or 3 wafer/clip seals inline.

If you need innovative, creative solutions to your job challenges, please call us – we can help!